Walkwater Cooling Tower Water Treatment Technologies provide complete scale & Corrosion protection through its comprehensive range of Biocides, Scale and corrosion Inhibitors and Condensate corrosion control treatments. Our Product range covers capabilities in all the required applications ensuring optimum performance, asset protection and Industrial compliance.

Introduction

Cooling towers are heat exchangers that use water and air to transfer heat from air-conditioning systems to the outdoor environment. Most commonly, they are used to remove heat from the condenser water leaving a chiller. Cooling towers are usually located on rooftops or other outdoor sites. Because they are frequently out of sight, they are often neglected by operation-and-maintenance technicians, resulting in lower cooling-system efficiency. This document will help you adopt best practices for the efficient operation and maintenance of cooling towers.

Types of Cooling Towers

There are two basic types of cooling towers, open and closed (sometimes called direct and indirect).

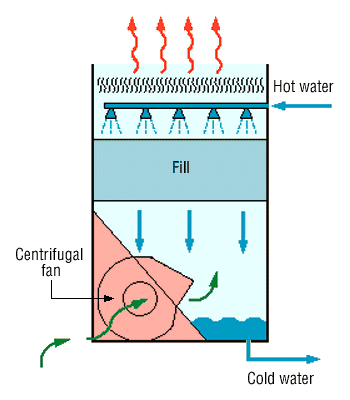

Open (Direct) Cooling Towers Open cooling towers expose the condenser water coming from the chiller plant directly to the atmosphere. This warm water is sprayed over a fill in the cooling tower to increase the contact area, and air passes through the fill. Most of the heat is removed by evaporation. The cooled water remaining after evaporation drops into the collection basin and is returned to the chiller's condenser.

Open (direct) Cooling Tower

Closed (Indirect) Cooling Towers

A closed cooling tower circulates warm water from the chiller plant through tubes located in the tower. In a closed tower, the cooling water does not come in contact with the outside air. Water that circulates only within the cooling tower is sprayed over the tubes and a fan blows air across the tubes. This cools the condenser water within the tubes, which is then recirculated to the chiller plant.

Closed (indirect) cooling tower

Key Components of Cooling Towers

This section explains how the components of a cooling tower work together.

Water Distribution

Hot water from the chilled-water system is delivered to the top of the cooling tower by the condenser pump through distribution piping. In an open tower, the hot water is sprayed through nozzles onto the heat transfer medium (fill) inside the cooling tower. Some towers feed the nozzles through pressurized piping; others use a water-distribution basin and feed the nozzles by gravity. In a closed-loop tower, the water from the condenser loop runs through tubes in the tower and is not exposed to the outside air. Water for cooling the tubes circulates only in the tower.

In the open tower, a cold-water collection basin at the base of the tower gathers cool water after it has passed through the heat transfer medium. The cool water is pumped back to the condenser to complete the cooling-water loop. In the closed tower, the condenser water cools as it moves through the piping in the tower and returns to the chiller plant.

Heat Transfer Medium (Fill)

Cooling towers use evaporation to release waste heat from an HVAC system. In an open tower, hot water from the condenser is slowed down and spread out over the fill. Some of the hot water is evaporated in the fill area, or over the closed-circuit tubes, which cools the water. Cooling tower fill is typically arranged in packs of thin corrugated plastic sheets or as splash bars supported in a grid pattern.

Air Flow

Large volumes of air flowing through the heat-transfer medium help increase the rate of evaporation and the cooling capacity of the tower. The cooling-tower fans generate this airflow. The size of the cooling-tower fan and airflow rate are selected to achieve the desired cooling at design conditions of condenser-water temperatures, water flow rate, and wet-bulb temperature.

Cooling towers may have propeller fans or squirrel-cage blowers. Small fans may be connected directly to the driving motor, but most designs require an intermediate speed reduction provided by a power belt or reduction gears. The fan and drive system operate in conjunction with the control system to control start/stop and speed. Variable-speed drives (VSDs), when added to the fan motors, control fan speed and more precisely regulate the temperature of the water as it leaves the tower.

Drift Eliminator

As air moves through the fill, small droplets of cooling water become entrained and can exit the cooling tower as carry-over or drift. Devices called drift eliminators remove carry-over water droplets. Cooling-tower drift becomes annoying when the droplets fall on people and surfaces downwind from the cooling tower. Efficient drift eliminators virtually eliminate drift from the air stream.

Safety Issues

Water Treatment

Cooling-tower water must be regularly treated, generally with chemicals, to prevent the growth of harmful bacteria, minimize corrosion, and inhibit the buildup of scale (mineral deposits) on the fill.

Maintenance Personnel

Cooling towers are often placed in precarious locations, and inspection ports can be located in awkward or exposed locations. This can create a hazardous working environment. Be sure to implement adequate fall-prevention measures and procedures. In addition, always follow lock-out and tag-out safety procedures. |